The scythe was an invaluable tool on farm and home properties in the first half of the 20th Century and prior. The tool with its six foot long, ergonomically designed, sensuously double-curved handle was a favorite of artists who portrayed the Grim Reaper. Sometimes the curved blade was three foot long. Even longer blades were used for grain and some shorter than two feet were used for heavy brush. The versatile scythe, with its interchangeable blades, was critical to harvesting hay, wheat, and other grains as well as trimming yard grass and last year’s raspberry patch.

By keeping the tool extremely sharp a farmer could reduce his labor nearly in half. A honing stone was always carried in the back pocket or in a holster while implementing the tool. Different coarsenesse sharpening stones were produced from varying mineral deposits. (A deposit found not far north of Bonneauville was exploited in the 19th Century). Even though the stones were hand cut (usually a cottage industry) the shape was important less the user loose a fingertip or two to the edge of three foot long highway of razor-sharp steel. There was a knack for sharpening a scythe that was almost art-like. Every couple hundred yards in a field the job was done deftly while taking a break and gazing far away for a few moments. It was a functional break from the constant six foot eye focus. Muscle fatigue and the awkward steps required to operate a scythe were taxing.

It was critical that children did not use scythes for two reasons. One was due to the length and sharpness of the blade, and the risk of horrible lacerations. Extreme control and stamina were required to operate the tool. Although the plants were generally cut just a few inches above the ground the slightest drop in the height of the blade could nick a rock. More specialized tools (a denglestock and a scythe hammer) were needed to correct that damage. Such errors could easily cost a farmer a couple of hours of repair labor. Young ones learned early that you simply do not touch grandpappy’s scythe.

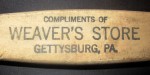

Scythe honing stones were worn down every few years. It was likely sometime after the year 1900 that honing stones made from natural sedimentary materials began to be replaced with man-made materials. The mass-produced pieces could be more perfectly shaped. They were produced at a very low cost. Some marketing-minded genius deduced that a flat surface on both sides of the tool was all that was needed for some advertising. It worked for pens and pencils, and it worked for matchbooks. Why not appeal the farmer every time he pulls his oft-used honing stone from its storage.

Weavers Stores have operated in Bonneauville for three generations. Under the ownership of first generation John Weaver, the address for his Bonneauville store was RD#5, Gettysburg, PA. It is believed by Weaver family members that this stone, printed “Complements of Weaver’s Store, Gettysburg, PA” was a John Weaver gratuity to faithful customers.